|

case study | automotive |

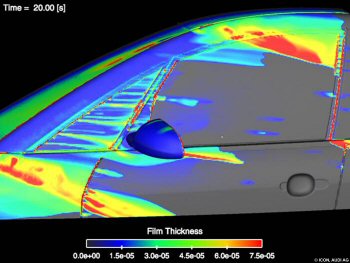

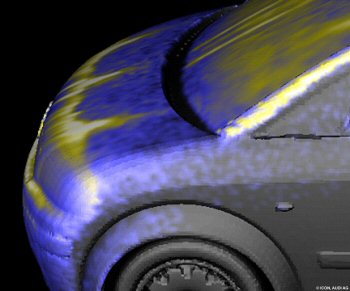

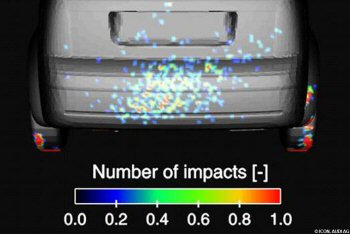

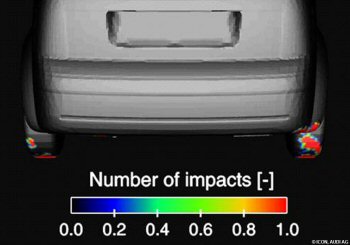

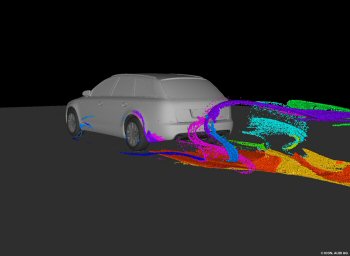

Harpoon used in Audi Vehicle Soiling Study by Bob Cramblitt and Paul Gilfrin Small things often sell cars and create brand loyalty: the positioning of the cup holder; how the seat molds to your body; the thunk of the door when it closes. Add to that list how particles – whether they are rain, snow or dirt – disperse across the surface of a car. Particle behavior in relation to the surface of a car is known in the automotive industry as vehicle soiling, and up until recently, it was nearly impossible to simulate in a computer. But within the last few years, Audi has made major strides in using CFD simulation and visualization to better predict the complex interactions that constitute vehicle soiling. Audi’s research has been made possible through a confluence of technological developments, including supercomputing-like power on low-cost PC clusters, new meshing software, engineering solver code that can handle two-phase flow models, and visualization software that enables researchers to see complex surface-particle interaction over time.Hidden complexity But, there’s more going on than meets the eye, according to Dr. Moni Islam, who works on vehicle soiling research at Audi’s wind tunnel center. Dr. Islam says that accurately simulating the effects of rain on the surface of a car requires taking several major issues into account, including size and velocity of raindrops, their impact on solid surfaces, speed of the car, the formation and transport of liquid film, and how liquid film breaks up when faced with aerodynamic forces. Additional complex properties to consider include the characteristics of particles generated from the road surface and the wheels of a moving car, the geometric details of the vehicle surface, and the unique interaction between solid particles and a solid surface in the case of snow and dirt deposition. Since 2003, Audi has been working with Icon, a CFD services company, to simulate and visualize these complex factors, and to validate the results from wind-tunnel and field tests. The research holds the promise of being able to accurately predict soiling early in the product development cycle. This would allow Audi to produce designs that further minimize build-up and improve dispersal of rain, snow and dirt on a car’s surface, leading to greater driver and passenger comfort. From physical to virtual testing Road testing is performed to determine soiling on the rear of the vehicle, such as dirt or snow collected on the bumper from the road surface and tires. While effective from a qualitative standpoint, wind-tunnel and road testing are expensive and require physical prototypes. Computer simulation is unlikely to replace physical testing altogether, but it can save substantial time and money in the early stages of new vehicle development. It can also improve quality by allowing engineers to assess soiling characteristics early on, and tweak their designs for greater efficiency. Exploring new techniques The simulations are made possible by two-phase modeling capabilities in STAR-CD, CD-adapco’s CFD software. STAR-CD offers both two-phase Lagrangian models – an approach for time-resolved simulation of discrete particles – and liquid-film models. Where once processing of the sizable models used by Icon – up to 75 million cells for meshing and 20 million cells for visualization – would take expensive supercomputers to process, they can now be handled by low-cost Linux clusters. Icon uses a network of 32 AMD Opteron CPUs running Suse Linux. The process begins with a CATIA assembly provided to Icon by Audi. Models typically contain hundreds of thousands of components and take up tens of gigabytes of storage space. They are often imported from CATIA to ANSA preprocessing software for what is known as “CAD surface preparation” – manipulating the CAD surfaces to fulfill the requirements of the meshing software. Automated hex meshing “It would take several weeks for us to hand-build the type of block-structured meshes we needed,” says Weston. “This limited the number of tests we could perform in the time we had available.” Icon was able to overcome this obstacle by using Harpoon “We prefer to use hexahedral cells whenever possible, and we’ve found Harpoon to be a powerful tool for building predominantly hexahedral meshes,” says Weston. “Usually, the trade off is that hex meshes are consuming to create, but Harpoon can create large and complex meshes in minutes.” The automated software has enabled Icon to shift much of the time that used to be taken building meshes into doing more simulation and analysis work. “We now have the time to analyze our designs in more detail and increasingly perform larger and more complex simulations,” says Weston. “We can perform multiple runs of complex meshes and thereby save our customers money on engineering development and testing.” Modeling real-world behavior A liquid-film model within STAR-CD is linked with a splashing model that predicts the behavior of droplets hitting a solid surface, such as the car’s hood, windshield or back bumper. The models simulate droplets as they bounce, adhere to the surface, or splash; depict how droplets form the liquid film; and show how the film behaves when confronted with aerodynamic forces. STAR-CD captures liquid-film qualities such as temperature, thickness, mass and velocity. “The splashing model and liquid-film transport models within STAR-CD are really what make it possible to simulate these complex interactions,” says Weston. “Low-cost cluster computing systems are important as well, since they enable us to easily manage computing resources without buying supercomputing time.” Revealing visualizations “We can read in everything from STAR-CD into EnSight, and even extract certain data not otherwise available,” says Francisco Campos, a consultant and CFD engineer for Icon. “The impact of droplets on the surface, statistical quantities, droplet size and volumes – all of this can be brought into EnSight for high-end visualization.” The major capability that EnSight provides for Icon’s work is visualization of transient data – animations and interactive objects that show how selected elements behave over time. “It’s simple to create the time steps, plug-in quantities such as temperature and droplet diameter, and then look at the graphical data any way you want,” says Campos. “And, you can create a script that can then be applied to similar cases.” The 3D visualizations enable Icon to see details that would not be visible by other means. “We can look at very small droplets, determine when droplets become film and how the film drops off the car,” says Campos. “We can filter out certain data to get a clearer view and isolate droplets from the liquid film.” According to Weston, the value of EnSight visualizations extends beyond research. “It’s a powerful tool for studying the results of our simulations and communicating them to Audi and within our own organization.” For further investigation… In general, qualitative simulations that realistically depict behavior and can be verified by wind-tunnel and road tests have been promising. Further testing is required to collect more detailed quantitative data and compare it to physical testing results. Work is also needed to simulate certain conditions seen in wind-tunnel tests, such as water streaks. Water streaks are highly dependent on small geometry features and microscopic surface properties, and have inherently stochastic behavior, both of which are currently not part of the simulation model. Audi’s present research is focusing on particle behavior on the vehicle’s surface. There are external factors that add to this complex picture, according to Dr. Islam, including unsteady air flow and turbulence, interaction with other vehicles, and road and tire surface characteristics. There is little doubt that accurately predicting vehicle soiling through computer simulations – and applying this method as a standard part of the development process – will be a major challenge for years to come. But, the combination of Audi’s aerodynamics expertise and dedication, Icon’s expertise in applying CFD and visualization to the problem, and the ever-quickening pace of technology development make the road ahead clearly visible.

|

Soil deposition at the RUAG Aerospace wind tunnel Visualization of film thickness over time. Wind tunnel results showing formation of water film on

Results of water

film forming on the front of an

Soil deposition at the rear of an Audi car.

Soil deposition on the tires of an Audi car.

Water droplets dispersing from an Audi car.

|